Village Industrial Power

Village Industrial Power

Energy on Demand

What We Do

Village Industrial Power is a social enterprise startup commercializing innovative clean energy solutions for rural communities and industries such as tea estates and fruit growers in sub-Saharan Africa and India.

The Village Industrial Power (VIP) Combined Heat and Power Plant

provides on-demand electricity and hot water, enabling rural farmers to increase the value of their crops by up to 10x. Using agricultural waste as fuel, the VIP 10-40 creates thermal, electrical, and mechanical energy for a wide variety of uses, from transforming crops into value-added products to providing electricity and hot water to workers in remote areas. VIP power plants are currently available in East Africa and India.

The VIP Speedy-Dry Food Dehydrator is ideal for drying high-moisture crops such as mango, banana, pineapple and tomato, and can be powered by the 10-40 Combined Heat and Power Plant

in remote areas that are not connected to grid power.

INITIATIVES

-

Crop Drying

Photo By: John DoeLearn More -

Energy Generation

Photo By: John DoeLearn More -

Maize Processing

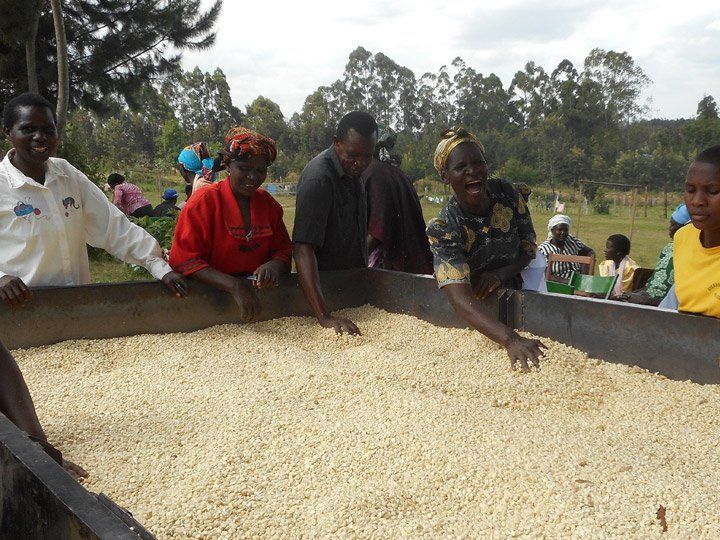

Learn MoreThis year VIP launched a mobile maize processing unit in Western Kenya. The engine runs a belt driven maize sheller producing enough waste cobs to both shell and dry maize.

-

Tea Estates

Learn More

-

Crop Drying

Learn More -

Energy Generation

Photo By: John DoeLearn More -

Maize Processing

Learn MoreThis year VIP launched a mobile maize processing unit in Western Kenya. The engine runs a belt driven maize sheller producing enough waste cobs to both shell and dry maize.